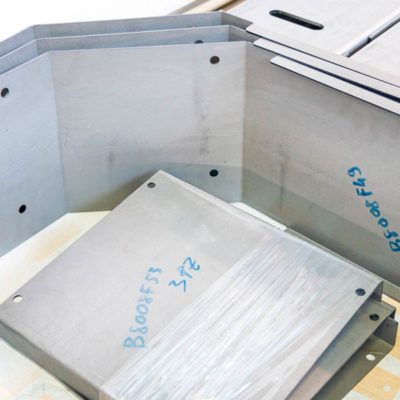

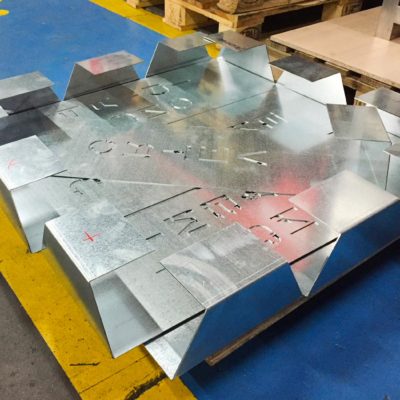

Sheet metal processing

From design to formSpadotto, follows the customer in all the phases of the sheet metal working process: from listening to the needs, to the design and processing of the prototype with CAD / CAM systems, to the subsequent laser cutting process, up to the bending phase with bending machines CNC, offering the highest quality products.

Competence, experience and professionalism make Spadotto a leading company in sheet metal working for manufacturing companies in the entire national territory.

With the perspective of the partner and the consultant Spadotto provides its customers with a technical office specialized in sheet metal working for any type of metal, able to support and advise to achieve excellent results, respecting time, costs and methods of work in every phase of the realization.

Sheet bending radius

The bending radius allows defining the deformation and consequently the maximum “bending of the sheet“.

The measurement of the internal bending radius must be equal to or greater than the thickness of the sheet itself.

To calculate the minimum bending radius, both the thickness of the sheet and the distance from the supports must be taken into account: the value of the internal radius grows slightly in the area of contact with the punch, while it undergoes a significant increase in correspondence with the supports.

Aluminum processing

Spadotto operates in the aluminum processing sector with 40 years of experience: sheet metal allows great adaptability to surface finishes of any level with excellent workability and a good dose of precision, which is why it is used in different sectors. The aluminum processing carried out by Spadotto is related to laser cutting, forming (bending, drawing and other processing), assembly of elements and finishing operations.

Stainless steel sheet processing

Spadotto, thanks to its know-how in the processing of stainless-steel sheets for different fields of application, offers the possibility of combining punching, laser cutting, sheet metal welding, sheet metal assembly and sheet bending, in order to create stainless steel sheets customized based on the project and customer needs.

Sheet metal processing Veneto

Spadotto is able to carry out all the stages of sheet metal processing, working for the most important manufacturing companies in Veneto and Northern Italy.

Spadotto uses press brakes, punching machines, deburring machines, welders and laser welding robots to carry out all the different processes of sheet metal processing: from shearing, to drawing, from bending to punching, all managed through a technical office that checks and verifies each project, following the different phases in order to optimize time and costs.